should you’re in the cookware producing company, obtaining the right machines to optimize your generation line is important. regardless of whether you’re generating stainless-steel, aluminum, or composite cookware, deciding on the ideal wholesale Laser Blanking equipment can noticeably impact your output and merchandise top quality. With advancements in laser cutting know-how, devices now give precision, speed, and automation customized towards the elaborate desires of cookware production.

Table of contents:

critical specs to Consider: electrical power, velocity, and precision

examining Compatibility with many Metals Employed in Cookware

Boosting productiveness to Meet Increasing current market requires

This information will wander you throughout the important technical specs, materials compatibility, and productivity Gains to take into consideration when deciding upon a Laser Blanking equipment, which include insights into best producers like JACKSON, noted for their abilities in cookware creation tools.

critical Specifications to contemplate: Power, Speed, and Accuracy

When selecting a Laser Blanking Machine for the cookware line, prioritize electric power, speed, and accuracy. Laser ability establishes the thickness on the metal you can Reduce proficiently, ranging from one.5KW to 6KW. large-electricity configurations are ideal for dealing with thicker metals like multi-layered composites, whilst reduce electrical power configurations are ample for thinner components like standard aluminum or chrome steel. velocity is yet another critical aspect, especially if you purpose to fulfill the higher-volume requires of aggressive marketplaces. hunt for slicing speeds of up to 30m/min for ideal productiveness. most significantly, don’t compromise on accuracy. equipment with precision amounts under 0.1mm assure clean, burr-totally free edges, getting rid of the necessity for additional ending processes and maximizing the standard of your cookware products and solutions. JACKSON, a renowned Laser Blanking device company, features devices Geared up with cutting-edge laser tech, automated loading, and stacking functionalities, which happen to be benchmarks of dependability and efficiency from the market.

evaluating Compatibility with several Metals Used in Cookware

Cookware output normally involves versatility, as unique products use numerous supplies for example stainless steel, copper, composite steel, and aluminum. make certain your decided on wholesale Laser Blanking Machine can handle these metals throughout different thicknesses correctly. As an illustration, JACKSON’s Laser Blanking devices guidance stainless steel (0.three–2mm), copper (0.3–4mm), and aluminum (0.5–4mm), covering a variety of manufacturing desires. This adaptability is particularly valuable for suppliers generating cookware with many levels, including tri-ply or multi-ply pans. Machines with Superior laser know-how, like These made by JACKSON, allow exact slicing across these elements, guaranteeing reliable effects regardless of the metallic kind. Also, the smooth, burr-no cost edges supplied by laser chopping minimize the risk of squander and rework, resulting in bigger effectiveness in the operations. By picking a device personalized to varied metals, you’ll potential-evidence your output line though preserving significant-excellent standards.

Boosting Productivity to fulfill rising market place calls for

The global cookware sector continues to increase, pushed by client demand for top-carrying out and durable kitchenware. To stay aggressive, suppliers will have to Improve efficiency with out sacrificing good quality. A higher-overall performance Laser Blanking Machine may be The real key to achieving this balance. options for instance automatic loading and uncoiling make these devices very autonomous, lessening labor expenditures and bettering operational effectiveness. car-stacking functionalities make sure Slice sheets are neatly gathered and organized, decreasing guide managing and saving time. Additionally, modern-day Laser Blanking equipment, which include These offered by JACKSON, can Reduce any condition in just a diameter choice of 60–1000mm, enabling manufacturers to produce intricate models that appeal to nowadays’s design-aware customers. The ability to handle superior volumes while preserving regularity positions your model for a trustworthy selection within the aggressive cookware current market. With JACKSON’s COOKWARE LINE laser methods, it is possible to boost efficiency, meet rising marketplace needs, and elevate your cookware output to the next level.

buying the best wholesale Laser Blanking equipment isn’t only a acquire; it’s a strategic move to boost performance, assure superior-quality manufacturing, and continue being competitive inside the swiftly evolving cookware market place. By evaluating crucial requirements like power, pace, and precision, guaranteeing compatibility with many metals, and concentrating on productivity-boosting options, you are able to decide on a device that satisfies your enterprise’s distinctive demands. Renowned brands like JACKSON offer tailor-produced alternatives that cater to your requires of cookware output, generating them a major choice for businesses trying wholesale Laser Blanking Machine , to enhance their generation strains. take a look at JACKSON’s Laser Blanking device offerings now and consider the initial step toward reworking your cookware manufacturing processes.

Haley Joel Osment Then & Now!

Haley Joel Osment Then & Now! Luke Perry Then & Now!

Luke Perry Then & Now! Alexa Vega Then & Now!

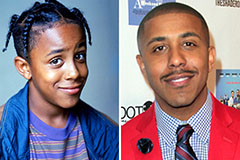

Alexa Vega Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Seth Green Then & Now!

Seth Green Then & Now!